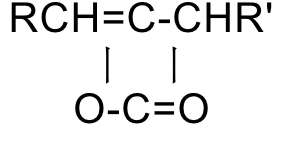

AKD emulsion is obtained from higher fatty acids (C>12) which is via acylation and dehydrochlorination, and it is emulsified from solid AKD wax together with the cationic auxiliaries, widely used as the neutral sizing agent in paper making industry.

It is a new generation product developed on the basis of the original neutral sizing agent. It has the characteristics of fast maturation, good stability, long storage period, and better water-resistant.

With the following features:

- By using the product, paper will be bestowed high water resistance, and the gloss of the paper is improved while yellowing rate is reduced.

- The product will help improve the printability of paper, increase the retention rate of fine fibers & fillers and reduce pulp consumption, which leads to lower costs.

- The product will help simplify the sizing process, improve the paper machine's paper-making performance, avoid paper-making obstacles, and obtain fast curing speed.

- Neutral papermaking will reduce equipment corrosion and extend equipment service life.

Specification

SPECIFICATION SHEET

| Item | Emulsion-12 | Emulsion-15 | Emulsion-20 | Emulsion-25 |

| Appearance | Milky white to slightly yellow liquid | Milky white to slightly yellow liquid | Milky white to slightly yellow liquid | Milky white to slightly yellow liquid |

| Solid content, % | 12.5 ± 0.5 | 15 ± 0.5 | 20 ± 0.5 | 25 ± 0.5 |

| PH Value | 2 - 5 | 2 - 5 | 2 - 5 | 2 - 5 |

| Ionic type | Cationic | Cationic | Cationic | Cationic |

| Viscosity, mpa.s @ (25℃), Min | 50 | 50 | 50 | 50 |

| Dispersibility | Easlily disperse in cold water | Easlily disperse in cold water | Easlily disperse in cold water | Easlily disperse in cold water |

| Usage | 1. The emulsion could be used in a wide pH value range (6-9) and is suitable for all types of pulp. 2. When usage in waste paper pulp, an appropriate amount of anion capture agent is recommended to add to attain better performance. 3. The recommended dosage is 5-15 kg, and usually it is fed continuously by a metering pump installed at the slurry mixing box or mixing box. |

|||

Note: Test values are provided for reference, and actual result may vary from different production lots.